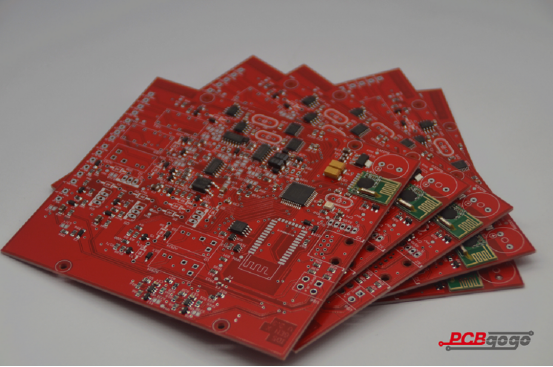

The purpose is to inspect and evaluate the solder paste deposit quality on each PCB. It’s known as automatic optical inspection. This part of the process can be automated thanks to the use of machines with This is the reason for the many inspection stages that follow.ģ.PCB Assembly – Solder Paste Inspection (SPI) Quality is something to look out for here this part of the PCB assembly is susceptible to environmental conditions such as In case you’re wondering, this solder paste is The stencil is removed after the solder paste application, and the solder paste stays in place. This has to be extremely precise, you can not add a bit more or a bit less, so at this stage of the PCB assembly process, we can expect a relatively high rate of defects. Then solder paste is applied on top of the stencil, filling all the openings.

Now comes the part of applying solder paste on the bare board a solder paste printer will only apply the solder paste on the areas where the components will be mounted as per the design in the Gerber files.Īt this stage, a solder paste printer and stainless steel stencil are placed on top of the bare board (PCB) and held together thanks to a mechanical fixture. With laser-marking machines is easy to select the number or QR code you want to print on the PCBs there’s of of course a software to upload the necessary files. The laser marking process is straightforward the PCBs go into the laser-marking machine a conveyor belt moves them through PCBs go under a low-power laser beam that marks them.

1.PCB Assembly – PCB Board and Laser Marking.

0 kommentar(er)

0 kommentar(er)